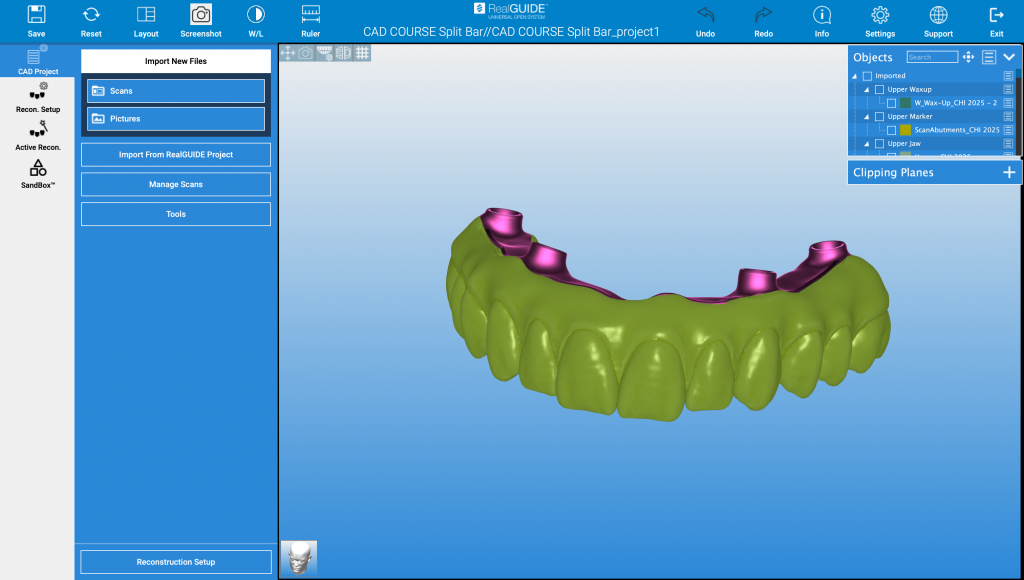

Back in April, we attended a course for RealGUIDE™ with Zimvie. The course focused on design workflow for a split bar case—an all-on-x fixed denture supported by a titanium bar. Thanks to the expertise and help of course directors Darren Emert and Casey Kahn, we were able to absorb a lot of information in a short amount of time.

RealGUIDE™ is not only a CAD software. It’s a collection of cloud-based programs for every step of the restorative process from implant planning and surgical guides to definitive design. What’s more, doctors and technicians using RealGUIDE™ can collaborate and communicate through each phase.

We were so pleased with the results of the course that we decided to take our design home and process it.

When manufacturing an all-on-x case with a digital workflow, first we print the upper and lower models in our Carbon 3D printer and place analogs in the implant sites. We don’t have to worry about any distortions in the printed model because Carbon’s printing tech is extremely accurate.

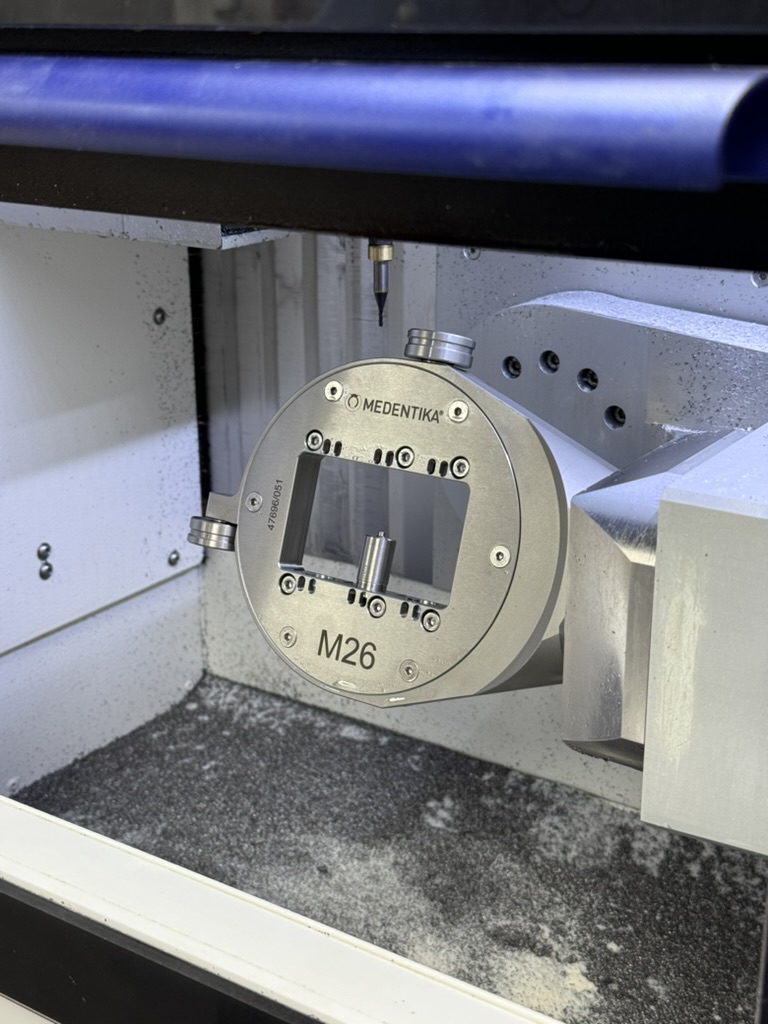

Next, we mill the titanium bar in our Imes Icore 350i™ mill. Cases like this underscore the benefit of having such a capable machine in-house. In little time, we have a precisely milled version of our design, and after some quick processing we can seat it on the printed model to verify a passive fit.

Then, we mill the zirconia arch in our Roland 52 DCi™ mill, which cuts an enlarged version of our design out of a puck of compressed zirconium dioxide powder. The result is a white arch that once baked (sintered) will shrink to our precise size and change color to the shade of zirconia we picked—generally, one of the sixteen Vita Classic shades or the bleach shades.

The milling job takes three to four hours, and then I can get to the fun part. Using a no.11 blade and a green state zirconia finishing kit from Wagner, I deepen the incisal embrasures, proximal contacts and the free gingival area, and I add some character and texture to the gingival portion.

It’s important that I take my time with this step. It is a vital part of the process that can easily be overlooked but makes all the difference between clearly false teeth and a lifelike restoration. The mill can only go so far in creating the depth necessary for these areas, and it takes a human touch to push the zirconia towards our standard of biomimetics.

Once the arch is fully crafted, I like to use some pre-sinter coloring to enhance the incisal character, chroma in the gingival third, and to add some color to the gingival area. Then, the arch is ready to go in the sintering oven overnight.

The next day, we have a beautiful zirconia arch ready to finalize. The real moment of truth comes when we place the titanium bar in the arch. There are a lot of variables at play when milling and sintering a large case that can distort the product, but when the proper protocol is followed the bar fits the arch like a dream.

I like to complete the esthetic phase in three bakes—one for color, one for glaze, and one for gingival texture. Using MIYO™ ceramic paste colors, I carefully create the illusion of a translucent incisal third which transitions to a higher value middle third and then to higher chroma leading into the gingiva.

With a variety of colors, I then create the illusion of translucent tissue in the gingival section, with higher pink saturation in the more vascular areas like the papillae and the alveolar mucosa, and lower pink saturation above each tooth to mimic the alveolar bone. I can also use fine streaks of different colors here to mimic veins.

Once those colors are baked, and after fully glazing the arch, I use MYIO Structure™ on the gingiva to complete the esthetic transformation. Structure not only adds color to what I’ve already placed, but with it I can create a texture mirroring natural tissue—complete with distinct papillae, labial frenum and stippling. The result after the final bake is a natural smile ready to be delivered.

Every esthetic restoration, from a single central to a full arch, is a challenging and humbling opportunity to return not only a patient’s function but also their smile. As always, we thank you for your continued partnership in that process.

Last month, we had the joy of again attending the Chicago LMT Lab Day conference. What a wonderful experience! Every year, we look forward to the excitement and opportunity of this trip, and this year we extended our visit to attend the CNC Group and Cal Lab meetings.

CNC Group offered enlightening seminars focusing heavily on All-on-X workflow. Dr. Brandon Kafford explained his streamlined technique for chair side conversions in which he uses liquid PMMA in the intaglio to create a quick, accurate, and durable temporary for immediate loading.

3Shape Senior Vice President of Product Strategy Rune Fisker showed us the new TRIOS IoConnect scan bodies for an edentulous arch, which eliminate the need for photogrammetry and accurately capture the arch using a regular intra-oral scanner, saving dentists the thousands of dollars it takes to acquire a photogrammetry camera.

The standout presenter at Cal-Lab was Rob Nazzal, founder of icortica, who outlined some of the current and future applications of AI in our field. Ai was a topic at the ’24 Cal Lab meeting as well, and it’s astonishing to see the speed with which that technology is growing (after his talk, Rob told us that he would be happy to give the same talk next year, but he’ll probably have to update everything in it). His talk mainly focused on programs he and his team are developing to facilitate communication between technicians and dentists.

The trip was worth these two meetings alone, but then the LMT Lab Day conference kicked off. In addition to an expansive exhibit hall where all of the major companies in dental tech supply show off their latest innovations, the conference rooms at the hotel were packed with educational opportunities from some of the leading talents in our field.

All-on-X was also the theme of Lab Day for us, and we attended some highly enlightening talks on everything from photography to lifelike esthetics. Two standout seminars were from Alexander Wunsche and Lukas Wichnalek, who outlined their workflow for completing highly functional and esthetic arches. I won’t go into the weeds here on all the ins-and-outs, but what struck me was the variety of options we have as technicians to process these cases, from a mixture of analog and digital to a fully digital workflow that doesn’t even need to involve a single model. With the right skills and a healthy working relationship, technicians and dentists are more capable than ever of restoring a full smile to those who need it most.

We capped off the trip with a series of seminars presented by RealGuide on their comprehensive cloud-based design software. RealGuide not only makes design easy, but makes it easy for dentists, oral surgeons, and technicians to communicate every step of the way, from planning to completion. We’ll be attending a more in-depth course on RealGuide in April, after which I’ll publish a newsletter dedicated solely to the software. Be sure to sign up for our newsletter so you don’t miss out.

The Chicago meeting was a wild success and a great way to start the year. Once again, we are energized and inspired to continue partnering with you to bring your patients the highest quality of care. As always, we thank you for your trust and your collaboration.

Here’s to a fantastic year!

If you read the first edition of our newsletter, you already know about our renovations in the lab, our adoption of cutting edge esthetic zirconias and our continuing education in esthetics and function. But we’re not done! The second half of 2024 saw several advances in the lab that will help make 2025 even better, not only for Selser Dental Lab but for you and your patients.

We are excited to announce that we are now a fully Encode empowered lab! In August, we were able to become an OEM (Original Equipment Manufacturer) of genuine Zimmer parts for Encode cases. Not only can we design custom abutments and crowns all from an Encode healing cuff, but now we are able to mill Encode abutments in-house and pass the savings (of time and money) on to you.

In the past, our only choice was to scan Encode cases, design the abutments and send those designs to Zimvie to be milled out of genuine Zimmer parts. While offloading the milling process might seem convenient, we would often end up having to let doctors know their case would be late due to production/shipping complications, and costs were also higher. Now, the production schedule is fully in-house, from scanning the models to milling the abutments and crowns to completing the case. And we are happy to pass the savings on to you!

September saw even more savings, as we brought down prices for our Value DSO line. Everyone has felt the strain of inflation this year, so we thought we would do what we could to ease that burden by adjusting our fee schedule. While prices everywhere are going up, we decided to cut prices for our full line of value products. The quality and guarantee remain the same, but at a lower cost to you.

Meanwhile, we also launched our Premier Esthetic line of in-house work. Charles and I developed the mission for Premier Esthetic at the 2024 Chicago Lab Day meeting. We were inspired not only by the incredible technicians we met at the conference but also by the collaborative partnerships so many of them have with their doctors. Our vision for Premier Esthetic is to provide top-tier esthetic restorations in collaboration with our dentists to deliver the highest quality results for your patients. Premier Esthetic goes beyond the simple shade tab crown to reproduce the intricacies unique to each patient’s smile.

Most recently, we launched a new customer portal to make the whole process more convenient. You are now able to create an account, send us cases, and pay your bill all from a link on our homepage. Click here to try it out.

As 2024 draws to a close and we look ahead to the new year, we at Selser Dental Lab could not be more grateful for your partnership. By working closely together in a truly collaborative way, we hope to keep bringing smiles to the countless people who need them most. Thank you for all you do, and Happy New Year!

2024 is shaping up to be a transformative year! Over the past several months, we’ve worked to streamline our layout and make our lab more of an efficient workspace. Much of our old workspace has been re-dedicated to digital design. We’ve also brought a warmer feel to our space by replacing old countertops and creating a kitchenette space for our team to fix their lunches or grab a cup of coffee.

Dentistry is a fast-changing field, and we’re dedicated to staying at the forefront of that change. It is in that spirit that we’d like to introduce you to one of Ivoclar’s most popular new products—E.Max Prime and Prime Esthetic zirconia.

As you know, full contour zirconia’s greatest drawback is a lack of true translucency compared to natural dentition. However, with E.Max Prime and Prime Esthetic, Ivoclar has managed to produce a functional zirconia that offers strength in stress areas and life-like translucency in the incisal region.

They achieved this by combining zirconia powders stabilized with varying amounts of yttria. The higher the level of yttria content, the higher the translucency with a corresponding compromise of flexural strength. With their proprietary gradient technology, Ivoclar has created a true multi-powder zirconia with less yttria in the cervical and middle area and more in the incisal. The result is a life-like, esthetic full contour crown with less influence from the stump shade. That means fewer remakes on implant cases and cases with a dark stump shade.

In February, we continued our pursuit of education by attending the Chicago Lab Day held in conjunction with the Mid-Winter Dental meeting. We look forward to this trip every year, and it did not disappoint. We had the opportunity to meet many fantastic technicians from around the world and pick their brains about the techniques and products they use.

We also attended the Cal Lab meeting, held at the same time in Chicago. Much of the Cal Lab meeting focused on the future of AI in dentistry. AI can be a scary topic for technicians of any field, but we left feeling invigorated and optimistic about it will improve the dental experience for everyone—patient, dentist, and technician.

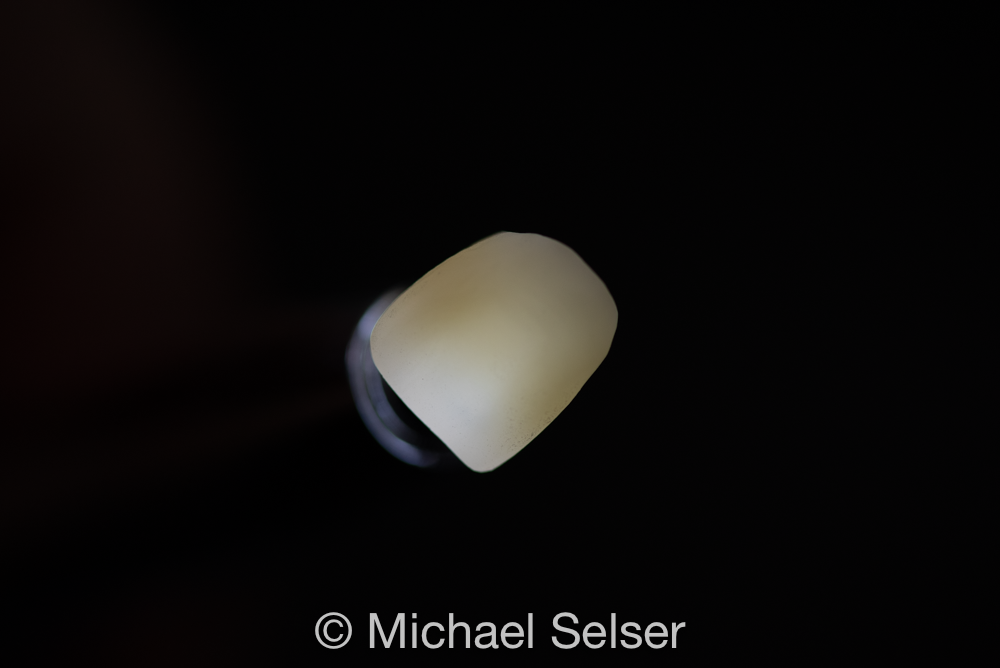

In May, I attended a course on full-arch workflow taught by renowned German ceramist Stefan Picha. We worked through the digital design stage of an all-on-x case, and had hands-on experience micro-layering porcelain and stain over a zirconia substructure. I always love attending these courses because they give me a chance to practice new techniques under the supervision of masters. Below you can see an image of the study case we completed, with stunning esthetic results.

We’re excited about what the future holds, and we thank you for continuing the journey with us. Your dedication to providing quality care for your patients always motivates us to do and be better.

—Michael Selser

Ceramist, Digital Specialist

Selser Dental Lab